Availability: 2 in stock

Estimated Arrival: Between Apr 18 and Apr 24. *ETA to USA Only

Shipping & Returns: Free Shipping U.S.A wide for All Orders Over $99!

Flashforge Guider 2S 3D Printer Large-Format with High Temperature Nozzle for Industrial and Personal Use

Product Description

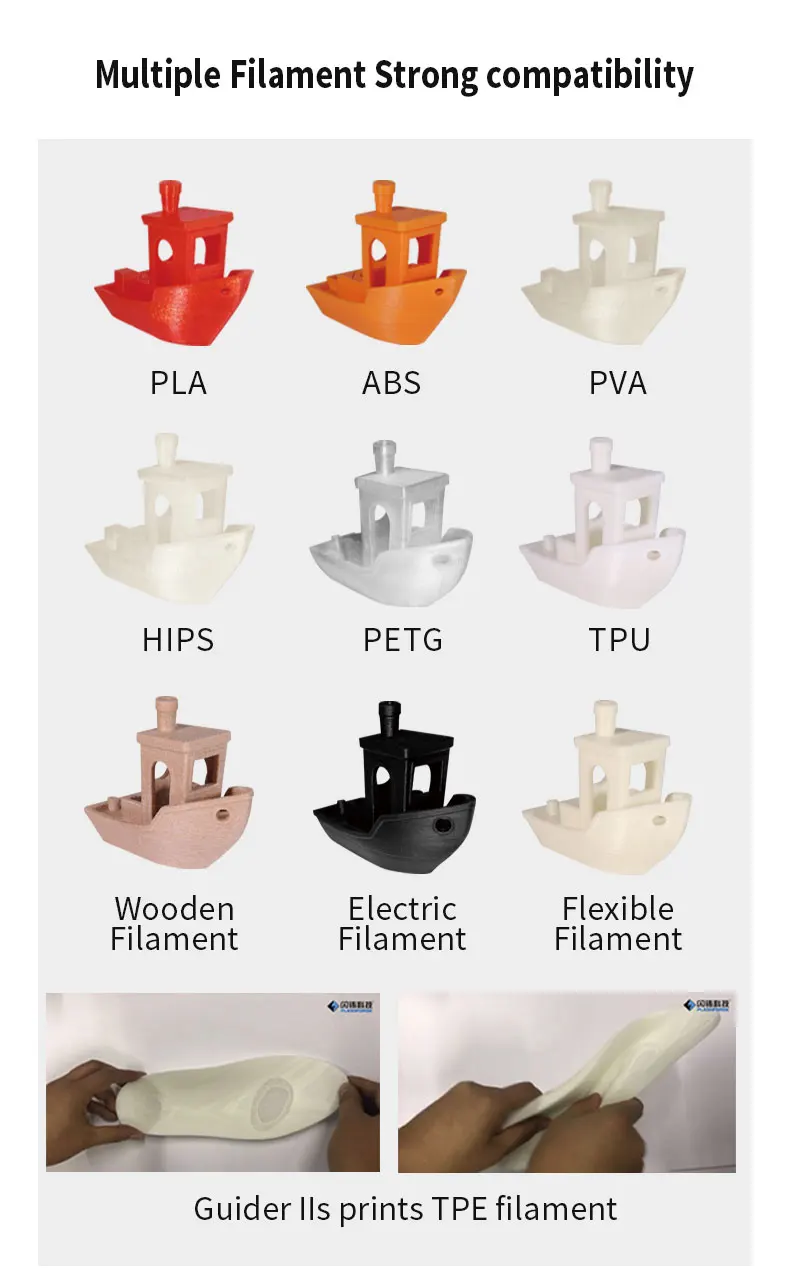

Flashforge Guider 2S, upgraded based on Guider II, is an industrial 3d printer boasts a durable extruder for max printing of up to 300℃. It prints big 3d objects using 10+ 3d materials (Nylon, PP, etc.) with professional quality and furthest stability.

Main features:

- Out of the box: pre-built 3d printer, start 3d printing after filament spool mounting and bed leveling.

- Build volume 280*250*300 mm, layer resolution 0.1-0.4 mm, print resolution ±0.2 mm, print speed 10-100 mm/s.

- 300℃ patent extruder and 120℃ heatable build bed : print PLA, ABS, PETG, PC, PA, Nylon and other industrial grade filaments. Bonus 1 spool of random filament(1000g).

- Open filament system & filament detection: compatible with most third-party FDM 1.75mm filaments. Cease printing when filament runs or interrupted.

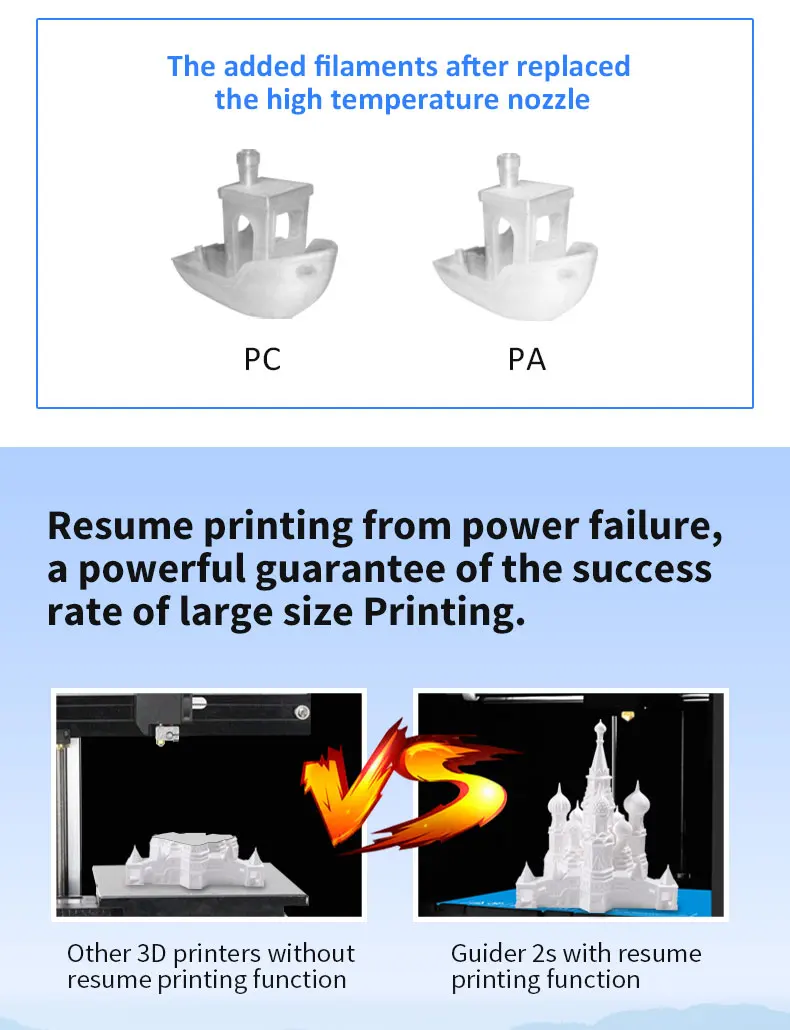

- Resumes printing from power failure: resume 3d print from sudden power blackout, saves filament waste and increase success rate.

- 5 inch touchscreen: streamline 3d print operation, save time and strength for volume production jobs.

- Powerful yet FREE slicer support: FlashPrint offers basic 3d model slicing features and advanced options such as editable support structures.

- Cloud printing: control multiple printers on cloud, greatly improves printing efficiency.

- Built-in Online camera: monitor 3d printing process remotely via WiFi and Cloud.

- Power conservation: turn off light bar to save energy, friendly for all-night printing.

- Air filter: effectively filter out fine dust produced when printing industrial 3d filament.

QUESTIONS & ANSWERS

Ask a Question-

Print result is ellipse when we set to print perfect roundness, and print result is rhombus when we set to print rectangle.

Step 1. X-Axis is not vertical to Y-Axis: Check the verticality between X-Axis andY-Axis,adjust the X-Axis vertical to the Y-Axis.

-

Extruder is moving to the right side without stop when printing.

Step 1. X-Axis sensor wire has loose contact or has problem: Reconnect the X-Axis ensor wire, if problem remains, replace with new X-Axis sensor wire. Step 2. If Step1 not solving, trigger iron piece of the X-Axis sensor has dropped off orhas problem: Replace with new X-Axis sensor.

-

Extruder temperature does not go up when preheating or loading filament.

Step 1. Heating pipe joint is disconnected with heating pipe: Reconnect these two parts back. Step 2. If Step1 not solving, heating pipe joint is disconnected from the exchange board: Weld the heating pipe joint back if you are experienced in welding, or please replace with new exchange board

-

“1025” extruder temperature showed on printer’s touchscreen when heating or printing.

Step 1. Extruder thermocouple has loose contact or has problem: Reconnect the extruder thermocouple to check, if problem remains, replace with new extruder thermocouple.

-

Extruder shakes from left and right when printing.

Step 1. X-Axis motor cable has loose contact: Reconnect the X-Axis motor cable tocheck, if problem remains, replace with new X-Axis motor cable. Step 2. If Step1 not solving, X-Axis driver board has problem: Replace with newX-Axis driver board.